"Rubber" is the most important element for all two-wheeled vehicles due to the only component that contacts the surfaces is tires. Rolling tires presents grip and it allows motorcycles to grab surfaces, so that riders could handle a motorcycle includes acceleration and deceleration.

An easy way to decelerate is closing throttle to cut off power delivery to drive wheel. But the efficient way is using brake system. Normally, riders could apply brake(s) to obtain better decelaration rate effectively. But to manage an emergency brake well is not an easy task for most riders due to lack of professional training and practices. The crucial factor to distinguish a successful emergency brake from a failed one is wheel spin. Adrenalin can drive riders to apply excessive force to brake system and result in wheel lockup or skid (stop spinning), which means loss of grip. A moving vehicle without grip is lost control. In short, it's easy to lock up wheels and lose control in an emergency brake. But how to creat maximum brake force and also maintain control in an emergency brake?

As mentioned, a rolling tire presents grip and in control motion, a well-trained rider can maximize brake force without locking up wheels in an emergency brake, which means reaching most efficient deceleration rate along with controllable motion. ABS provides regulated maximum brake force when riders apply excessive force to assist riders to avoid wheel lockup and also maintain control. Generally speaking, certified riding skill trainings and ABS support are riders best aid for emergency brakes.

ABS was first applied in aviation, for safer aircraft landing. Compare to unpredicatble brake distance casued by wheel lockup, ABS can stop an aircraft efficiently to prevent incidents from happening. After decades of developement, modern ABS is downsized to adapt motorcycles and has become sophisticated electronic controlled hydraulic mechanism. Typical or base type motorcycle ABS is designed for straight and upright vehicle movement. 2-channel ABS is the mainstream in the industry and is widely equipped on SYM scooters and motorcycles, this type of ABS gives not only front wheel but also rear wheel antilock capability.

ABS processing unit collects and calculates wheel speed signals to judge lockup or rolling. Pressure control (antilock) procedure will be activated on the hydraulic unit to release or maintain pressure when processing unit determines to intervene, this is why riders can feel feedback from brake levers or brake pedals. By the way, riders should not loosen brake force when feeling such feedback, or processing unit will suspend antilock procedure. What's more, modern ABS are able to compare front and rear wheel speed difference when braking for more accurate judgement.

Take the edge-cutting BOSCH 10.3MB for example, as the latest generation ABS, BOSCH 10.3MB has downsized and weight reduced compact body and enhanced braking force. What’s more, it integrates flooting point unit (FPU) chip that brings faster computing performance. In close collaboration with BOSCH, SYM R&D chassis engineering team blended thier profound experience into the braking performance tuning for SYM models. All BOSCH ABS that equipped on SYM 2-wheelers were tested and tuned on various friction level surfaces. With smooth feedback, steady handling and extraordinary braking efficiency, riders could enjoy the prestige of owning SYM 2-wheelers.

BOSCH motorcycle ABS basic introduction clip

An easy way to decelerate is closing throttle to cut off power delivery to drive wheel. But the efficient way is using brake system. Normally, riders could apply brake(s) to obtain better decelaration rate effectively. But to manage an emergency brake well is not an easy task for most riders due to lack of professional training and practices. The crucial factor to distinguish a successful emergency brake from a failed one is wheel spin. Adrenalin can drive riders to apply excessive force to brake system and result in wheel lockup or skid (stop spinning), which means loss of grip. A moving vehicle without grip is lost control. In short, it's easy to lock up wheels and lose control in an emergency brake. But how to creat maximum brake force and also maintain control in an emergency brake?

As mentioned, a rolling tire presents grip and in control motion, a well-trained rider can maximize brake force without locking up wheels in an emergency brake, which means reaching most efficient deceleration rate along with controllable motion. ABS provides regulated maximum brake force when riders apply excessive force to assist riders to avoid wheel lockup and also maintain control. Generally speaking, certified riding skill trainings and ABS support are riders best aid for emergency brakes.

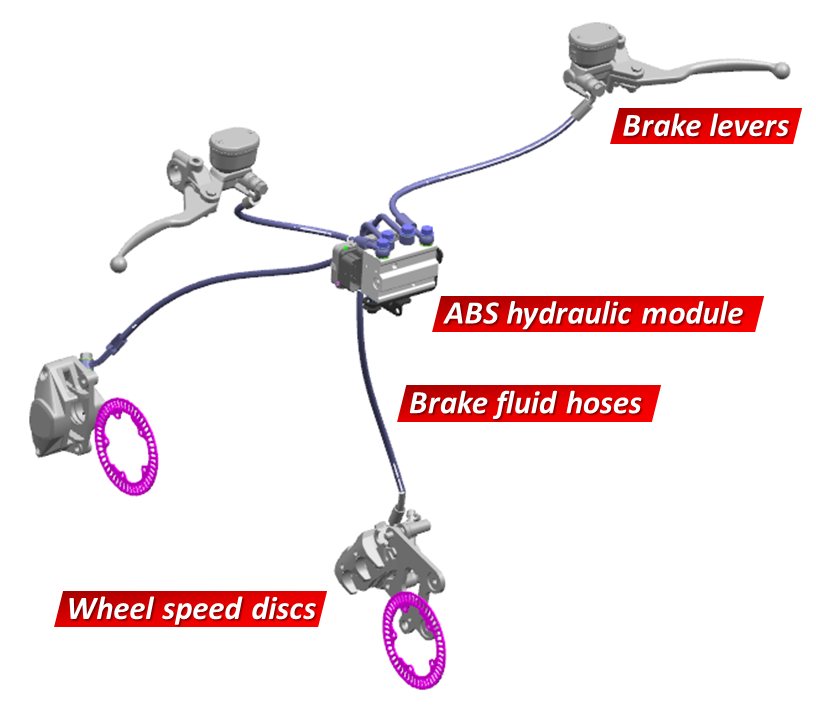

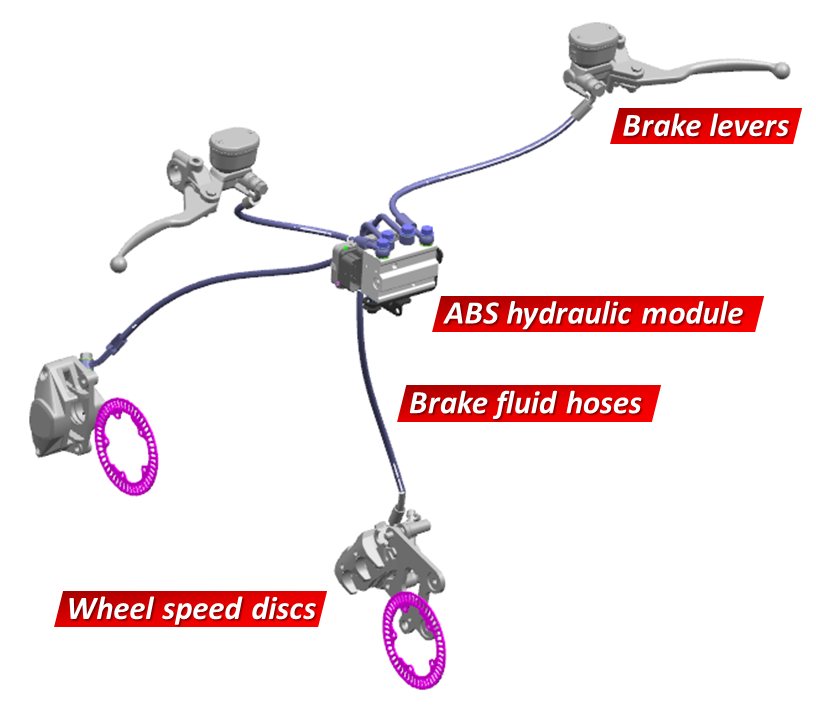

ABS was first applied in aviation, for safer aircraft landing. Compare to unpredicatble brake distance casued by wheel lockup, ABS can stop an aircraft efficiently to prevent incidents from happening. After decades of developement, modern ABS is downsized to adapt motorcycles and has become sophisticated electronic controlled hydraulic mechanism. Typical or base type motorcycle ABS is designed for straight and upright vehicle movement. 2-channel ABS is the mainstream in the industry and is widely equipped on SYM scooters and motorcycles, this type of ABS gives not only front wheel but also rear wheel antilock capability.

ABS processing unit collects and calculates wheel speed signals to judge lockup or rolling. Pressure control (antilock) procedure will be activated on the hydraulic unit to release or maintain pressure when processing unit determines to intervene, this is why riders can feel feedback from brake levers or brake pedals. By the way, riders should not loosen brake force when feeling such feedback, or processing unit will suspend antilock procedure. What's more, modern ABS are able to compare front and rear wheel speed difference when braking for more accurate judgement.

Wheel speed discs and wheel speed sensors create signals for ABS hydraulic module

Take the edge-cutting BOSCH 10.3MB for example, as the latest generation ABS, BOSCH 10.3MB has downsized and weight reduced compact body and enhanced braking force. What’s more, it integrates flooting point unit (FPU) chip that brings faster computing performance. In close collaboration with BOSCH, SYM R&D chassis engineering team blended thier profound experience into the braking performance tuning for SYM models. All BOSCH ABS that equipped on SYM 2-wheelers were tested and tuned on various friction level surfaces. With smooth feedback, steady handling and extraordinary braking efficiency, riders could enjoy the prestige of owning SYM 2-wheelers.

BOSCH motorcycle ABS basic introduction clip